International Visitors Tour Cailin’s Stone-Coated Metal Roofing Factory

- By: Cailin

- May 09 2025

International Visitors Tour Cailin’s Stone-Coated Metal Roofing Factory

Recently, international guests were welcomed at Cailin Roofing's advanced manufacturing facility, where they experienced an immersive tour that took them from raw steel coils to precision-finished roofing tiles.

From automated production lines to hands-on testing, this was more than just a factory visit — it was a firsthand look at Cailin’s commitment to quality and innovation.

From Steel Coil to Roofing Tile: Smart Manufacturing in Action

Standing before the towering, two-story raw material warehouse, one visitor looked up in awe at the 25-ton aluminum-zinc steel coils, calling them “the heart of a metal tile.” The journey of transformation began as the 0.45 mm steel sheet was automatically fed into high-speed stamping machines.

Each sheet danced through the press with rhythmic precision — 12 tiles per minute, molded into beautiful wave-shaped profiles.

"Only 0.5 mm deviation?" a guest asked in surprise, using a caliper to measure the tiles. The intelligent inspection system was also a highlight, instantly identifying and removing any imperfect products from the line.

By the end of the tour, the visitors had not only seen the production process — they had bent and beaten the tiles themselves. The verdict was clear: Cailin’s stone-coated metal tiles aren’t just beautiful — they’re built to last!!!

For these international professionals, the product didn’t need a sales pitch. The hammer test spoke louder than words!

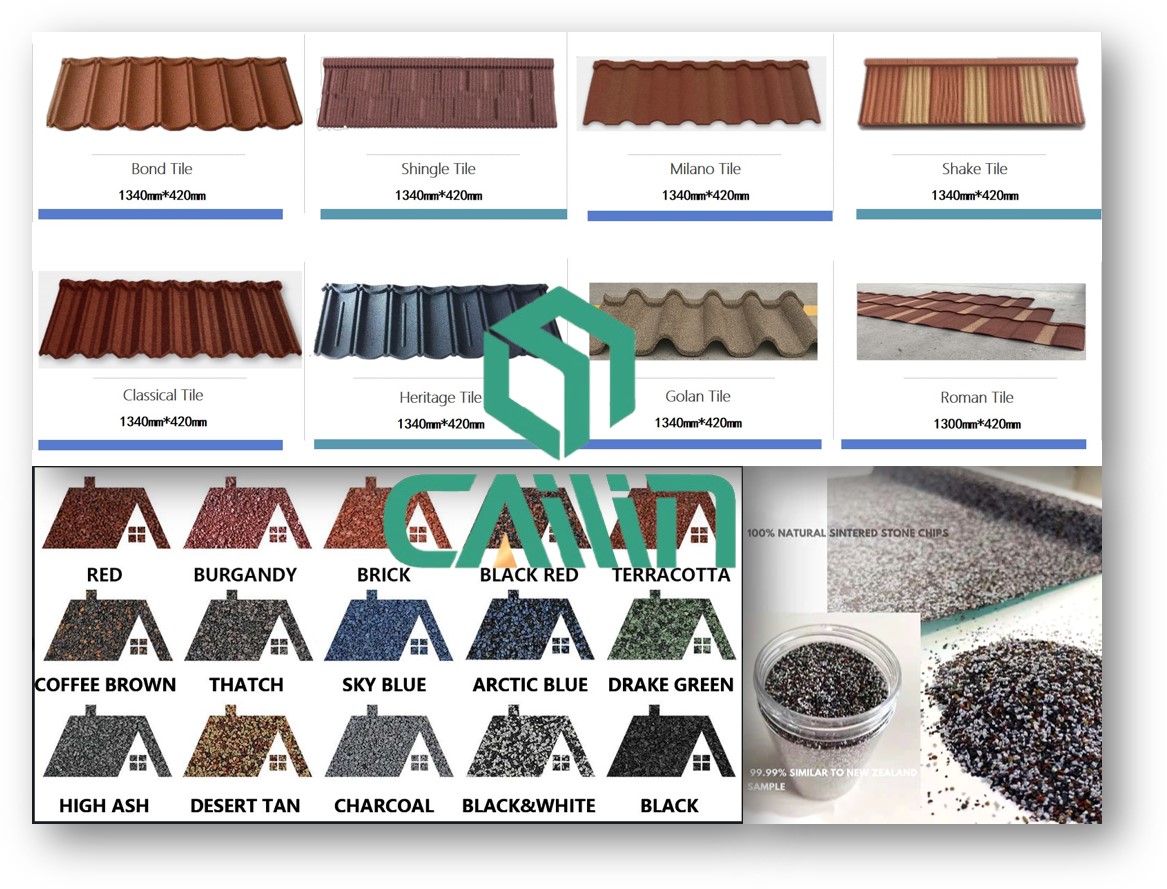

The Secret Behind the Color: Stones That Sing

When the group arrived at the stone-coating section, they picked up a handful of colorful granules and were introduced to one of Cailin’s signature strengths — color stability that lasts over 30 years.

These 3–5 mm Taishan basalt granules go through magnetic separation, acid washing, and are fired at 800°C before they ever touch the tile surface.

Only then are they ready for high-adhesion coating — one of the reasons Cailin tiles retain their vibrant colors in all climates.

Extreme Durability: Bent, Hammered, and Still Intact

At the quality control area, the visitors became testers themselves. One of the toughest demonstrations was a 160-degree bending test, far exceeding international standards.

Although the steel panel formed sharp creases, the stone coating stayed firmly in place, showing zero peeling or cracking.

Then came the hammer test. With three heavy swings, a technician slammed the surface — bang, bang, bang! Despite the force, the tile showed only a coin-sized dent, with no cracking or damage to the galvanized underside.